t51 drill bits Selection and maintenance

T51 Bits is a part of the T51 series of top hammering rock tools, mainly used for drilling operations. This series includes various drill bits and accessories with different diameters to meet the drilling needs of different depths and types of rocks.

Drill bit model and specifications:

The T51 series drill bits include various models, such as T51-89mm, T51-102mm, T51-115mm, T51-127mm, etc., with a wide range of diameters to meet different aperture requirements.

The drill bit adopts a spherical or parabolic button design, which helps to maintain stability and improve drilling efficiency during the drilling process.

Attachment type:

Dome bit for reaming: such as T51-152mm, it also has a spherical or parabolic button design.

Extension rods: such as T51-Round52-T51, with lengths including 3050mm, 3660mm, 4270mm, 4880mm, 5530mm, 6095mm, and other specifications to meet drilling needs at different depths.

M/F rods: also available in various length specifications, making it easy to connect and expand during drilling.

Guide rods and guide tubes: These accessories help improve drilling accuracy and stability.

Technical features:

The T51 bits have a flushing hole design with a diameter of 21.50mm, which helps to remove rock debris during drilling, maintain the cleanliness of the drill bit, and improve drilling efficiency.

The wrench flat has a size of 45mm, making it convenient to use a wrench for replacing or adjusting drill bits.

Applicable scope:

T51 bits are suitable for various rock drilling operations, including but not limited to geological exploration, mineral resource development, basic engineering construction, and other fields.

How to purchase T51 bits

When choosing T51 Bits, you can refer to the following steps and key points to ensure that you choose the right product:

Determine requirements:

Firstly, clarify the rock type, pore size requirements, and drilling depth for drilling, which will directly affect the selection of T51 bits.

Select drill bit model and specifications:

Select suitable T51 Bit models and specifications according to your needs, such as T51-89mm, T51-102mm, T51-115mm, etc. Ensure that the selected drill bit diameter meets the expected aperture requirements.

Considering technical characteristics:

Pay attention to the flushing hole design of T51 bits, which helps to remove rock debris during the drilling process, maintain the cleanliness of the drill bit, and improve drilling efficiency.

The size of the wrench’s flat surface is also a factor that needs to be considered to ensure that the wrench can be easily used for operation when replacing or adjusting the drill bit.

Consider attachment types:

According to the drilling depth and requirements, select suitable accessories such as reaming drill bits, extension rods, male and female joint rods, etc. Ensure that these attachments are compatible with the selected T51 bits and meet drilling requirements.

Pay attention to materials and quality:

The material of T51 Bits has a significant impact on its performance and service life. Priority should be given to selecting drill bits made of high-strength alloy steel and special heat treatment processes to ensure their wear resistance and durability.

Consider selecting manufacturers and brands with relevant certifications (such as ISO 9001:2000) to ensure product quality and reliability.

Comparing prices and services:

During the purchasing process, compare the prices and performance of T51 bits from different brands and models, and choose products with higher cost-effectiveness.

Pay attention to the after-sales service and technical support provided by manufacturers or suppliers to ensure timely and effective assistance during use.

View user reviews and cases:

Before purchasing, check other users’ evaluations and feedback on the product to understand its performance in actual use.

If conditions permit, it is possible to understand the application cases of the product in similar engineering or projects in order to better evaluate its performance and applicability.

What are the types of T51 bits

T51 bits usually refer to drill bits suitable for T51 Top Hammer drilling equipment. These drill bits have multiple types to choose from based on different rock types, drilling requirements, and pore sizes. The following are some common types of T51 bits:

Cone Bits:

Conical drill bits are suitable for various rock types, especially in harder rocks. They have great drilling ability and can maintain good stability during the drilling process.

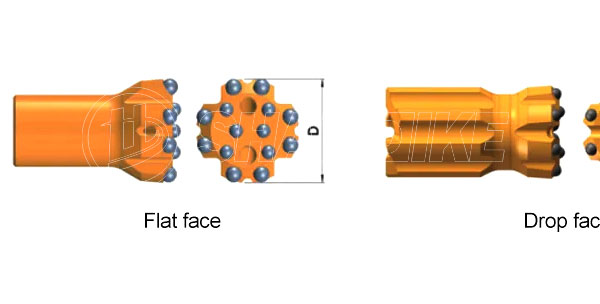

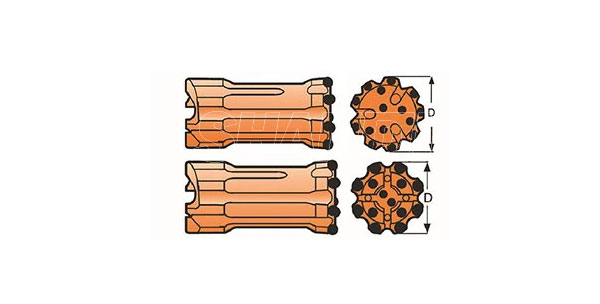

Button Bits:

Ball toothed drill bits are commonly used for medium hardness rocks, such as sandstone, shale, and some granite. They have good wear resistance and a long service life.

According to the shape and arrangement of the ball teeth, they can be further subdivided into spherical and parabolic ball tooth drills.

Dome bits for Reaming:

Expanding drill bits are usually used to further enlarge the aperture in already drilled holes. They usually have larger diameters and special structural designs to ensure the integrity and stability of the hole wall during the expansion process.

Pilot bits:

A directional drill bit is used to guide the drilling direction, especially when precise control of the drilling path is required. They usually have smaller diameters and special guiding structures.

Carbide bits:

Hard alloy drill bits are made of hard alloy materials, which have high hardness and wear resistance. They are usually used for drilling into hard rocks and highly abrasive formations.

Diamond bits:

Although diamond drill bits are not common in T51 systems, they may need to be used in certain special applications. Diamond drill bits have extremely high hardness and wear resistance, making them suitable for drilling in extremely hard and highly abrasive formations.

Other special drill bits:

According to specific application requirements, there may also be other specially designed T51 bits, such as drill bits with cutting teeth, drill bits with spiral grooves, etc.

When selecting T51 bits, factors such as rock type, drilling depth, pore size, drilling speed, and budget need to be considered. In addition, it is important to choose a manufacturer with a good reputation and reliable technical support to ensure the purchase of high-quality T51 bits and good after-sales service.

T51 Bits service life

The service life of T51 bits is influenced by various factors, including rock type, drilling depth, frequency of use, maintenance, etc. Therefore, it is not possible to provide an exact number to indicate its service life. But here are some considerations and general rules regarding the service life of T51 Bits:

Rock type:

The degree of wear of T51 bits varies when drilling into different types of rocks. When drilling into hard rock or highly abrasive formations, the drill bit wears out quickly and has a relatively short service life.

Drilling depth:

The deeper the drilling depth, the greater the pressure and wear that the drill bit bears, and its service life is relatively short.

Usage frequency:

High frequency use will accelerate the wear of T51 bits and shorten their service life.

Maintenance:

Regular maintenance and upkeep of T51 bits, such as cleaning and lubrication, can extend their service life.

Drill quality:

Choosing high-quality and wear-resistant T51 bits can extend its service life to a certain extent.

General pattern:

Under normal use and maintenance conditions, the service life of T51 Bits typically ranges from tens to hundreds of hours. But please note that this is only a rough range, and the specific service life may vary due to various factors.

If encountering abnormal situations during the drilling process, such as sudden increase in pressure, abnormal noise, etc., drilling should be stopped immediately and T51 bits should be checked to avoid further damage.

To extend the service life of T51 bits, it is recommended to take the following measures:

Select appropriate T51 bits based on rock type and drilling requirements.

Maintain appropriate drilling speed and pressure during the drilling process.

Regularly maintain and upkeep T51 bits to ensure they are in good working condition.

Pay attention to observing and checking the wear of T51 bits during use, and replace severely worn drill bits in a timely manner.

In summary, the service life of T51 Bits is a relatively complex issue that requires comprehensive consideration of multiple factors. By reasonable selection, correct use, and regular maintenance, its service life can be maximized.