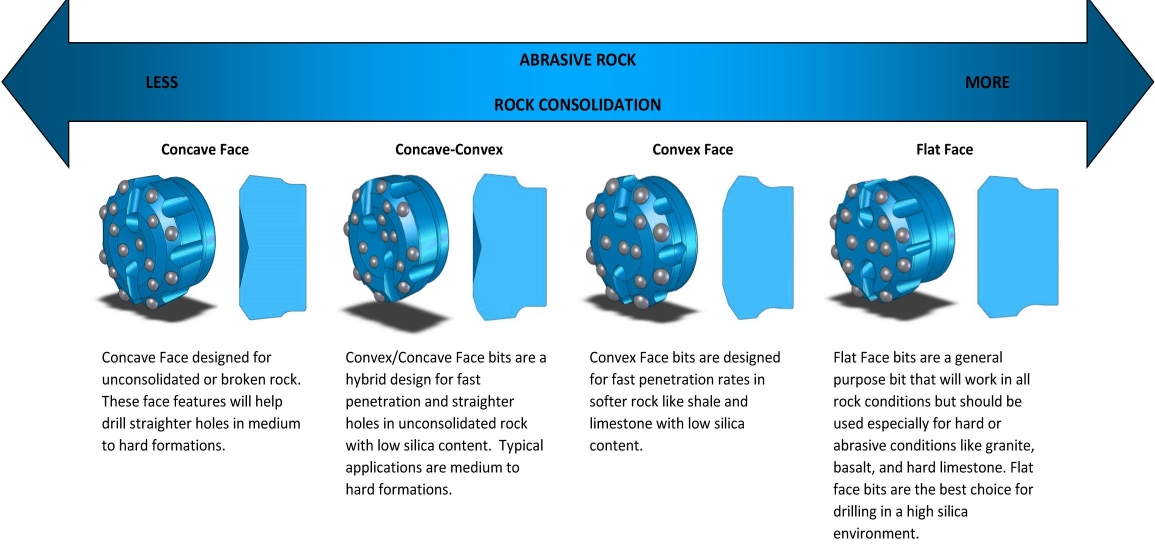

SHANDIKE ROCK DRILL BIT FACE SELECTION

TOP-HAMMER BUTTON BITS

The selection of TOP-HAMMER BUTTON BITS usually involves the following considerations:

Drill diameter: The selection of an appropriate diameter depends on specific drilling requirements, including rock hardness, pore size requirements, and drilling efficiency.

Drill bit type: According to the type and hardness of the rock, different types of drill bits can be selected, such as tapered button bits and threaded button bits.

Drill material: The selection of drill material is crucial for its performance and service life.

Drill bit structure: The design of drill bit structure directly affects its drilling efficiency and durability.

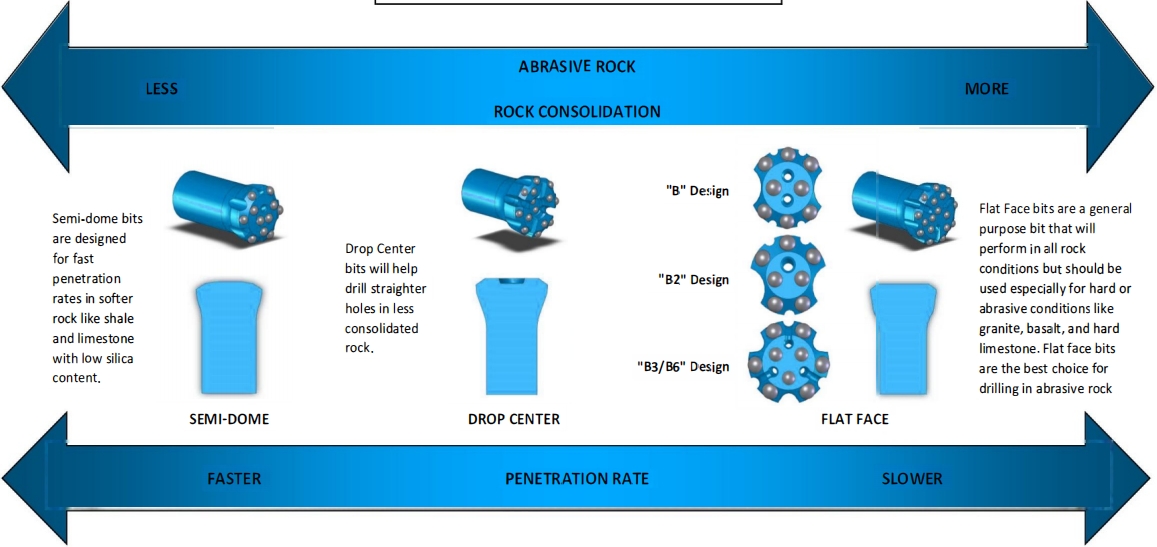

DOWN-THE-HOLE (DTH) BITS

CARBIDE SELECTION

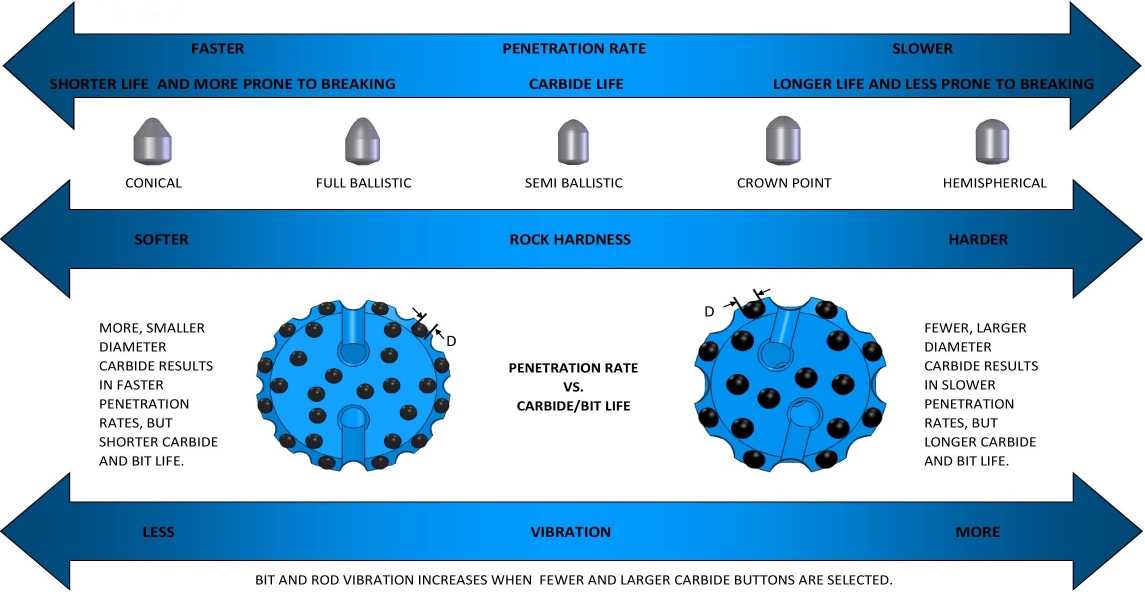

Carbide Designs

Perhaps the most fundamental decision when selecting differentcarbide configurations is profile shape.Button bits most commonlyhave either a hemispherical or semi-ballistic carbide design;howeverit is not uncommon to use other carbide designs as well.Below areselections of the different carbide designs offered by RockmoreInternational.

Carbide Configurations

Most face designs for button bits are offered in multiple carbideconfigurations and typically differ in diameter,shape (i.e.profile)andquantity.There are somegeneral guidelines to follow while selectingbetween multiple carbide configurations including resistance to wear,penetration rate,vibration,and specific rock conditions.

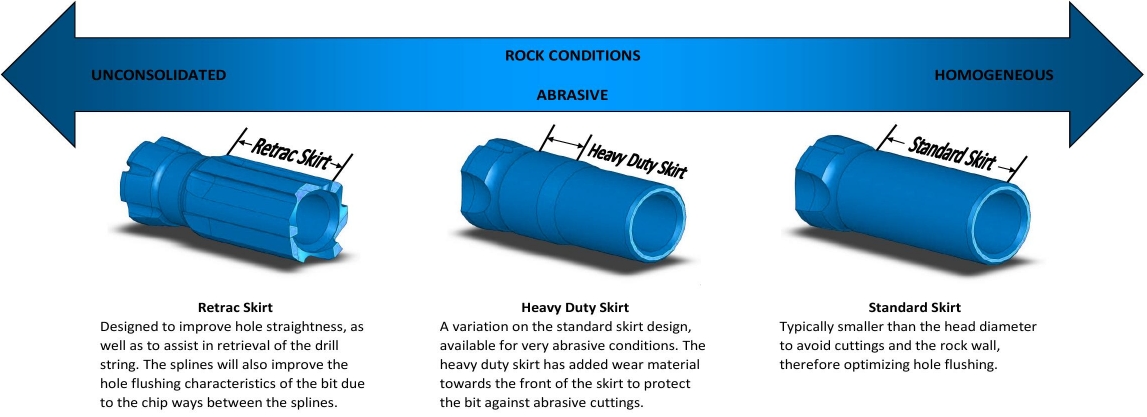

SKIRT SELECTION