Heat Treatment Methods for Tapered Drill Rods

Heat treatment of tapered drill rods is crucial to ensure they possess the necessary hardness, toughness, and wear resistance for drilling applications. The tapered geometry introduces challenges such as uneven cooling rates and potential distortion. Below are two primary heat treatment methods tailored for tapered drill rods, along with key considerations:

1. ThroughHardening and Tempering

Process Steps:

1. Austenitizing: Heat the entire rod uniformly to the austenitizing temperature (e.g., 830–870°C for 4140 steel).

2. Quenching: Rapidly cool in oil (preferred over water to minimize thermal stress) to form martensite.

3. Tempering: Reheat to 400–600°C to reduce brittleness and achieve a balance of hardness and toughness.

Benefits:

Provides uniform core hardness and strength.

Suitable for highcarbon or alloy steels (e.g., 4140, 4340).

Challenges for Tapered Rods:

Uneven cooling: Thicker sections cool slower, risking soft spots or distortion.

Mitigation: Use agitated oil quenching or polymer quenchants for controlled cooling.

PostTreatment:

Straightening may be required if warping occurs.

Hardness testing along the taper (e.g., Rockwell C scale) to ensure consistency.

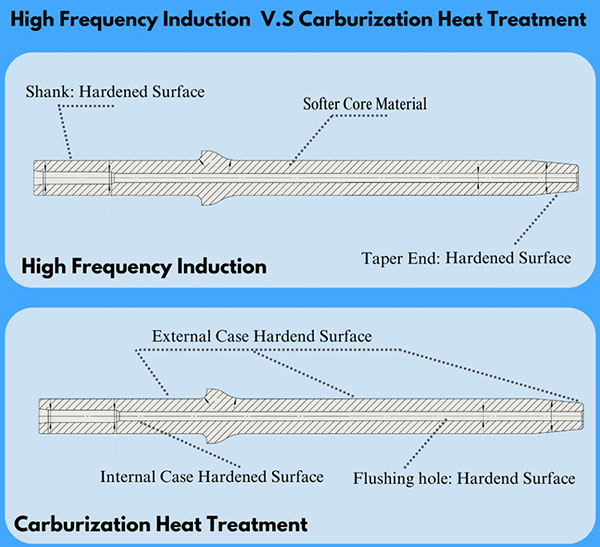

2. Induction Hardening

Process Steps:

1. Localized Heating: Use an induction coil to heat the tapered surface to austenitizing temperature.

2. Quenching: Immediate spray quenching (water or polymer) to harden the surface.

3. Tempering: Lowtemperature tempering (150–200°C) to relieve stresses.

Benefits:

Hardens only the surface, preserving a tough core.

Minimizes distortion compared to full hardening.

Ideal for applications requiring wearresistant surfaces (e.g., drill rod threads).

Challenges for Tapered Rods:

Coil design: Requires precise coil alignment to maintain consistent heating along the taper.

Variable case depth: Thinner sections may overheat; automated coil movement or variable power settings can address this.

PostTreatment:

Eddy current testing to verify case depth uniformity.

Additional Considerations

PreTreatment:

Stressrelief annealing after machining to reduce residual stresses.

Normalizing to refine grain structure for consistent hardening.

Alternative Methods:

Nitriding: Lowtemperature surface hardening (500°C) for minimal distortion.

Austempering: Interrupted quenching in a salt bath to reduce warping.

MaterialSpecific:

Highcarbon steels prioritize hardness; alloy steels (e.g., 4140) balance toughness and wear resistance.

By selecting the appropriate method and controlling process parameters (e.g., quench medium, coil speed), tapered drill rods can achieve optimal performance with minimal distortion. Posttreatment inspection is critical to ensure geometric integrity and mechanical properties.