A drilling button bit is a specialized type of drill bit characterized by its incorporation of numerous tiny, round, and highly durable tungsten carbide “buttons” or inserts embedded into its drilling face. These buttons function as the primary contact points, effectively crushing, chipping, and fracturing rock as the bit is rotated and pressed into the earth. This particular drill bit is ideal for applications in mining, construction, and various other drilling tasks. The R32 designation pertains to the thread size, specifically indicating a nominal diameter of 32 mm, ensuring compatibility with drill rods and shanks that adhere to this threading standard.

Specifications of the R32 Drilling Button Bit

The R32 button bit comes in a range of specifications tailored to specific requirements, including rock type, desired hole diameter, and drilling technique. Below are some common specifications for R32 button bits:

Button Bit Specifications:

Reaming Bit Specifications:

Structure Features of the R32 Drilling Button Bit

Button Design:

The defining characteristic of a button drill bit is the presence of buttons embedded in its head. These buttons are typically made of cemented carbide, such as tungsten carbide. The shape of the buttons allows for greater pressure to be applied over a smaller contact area when in contact with hard materials like rocks. In open-pit mining, for instance, the buttons act as mini “hammers,” facilitating the cracking and breaking of rocks.

Drill Body:

The body of the button drill bit is generally constructed from high-quality steel, serving as a sturdy support for the buttons. The design of the bit body ensures it possesses sufficient strength and toughness to endure the impact and torque encountered during drilling operations. The buttons are connected to the bit body through a specialized method, making it straightforward to replace worn-out buttons.

If you have any inquiries about the R32 drilling button bit, please feel free to contact us.

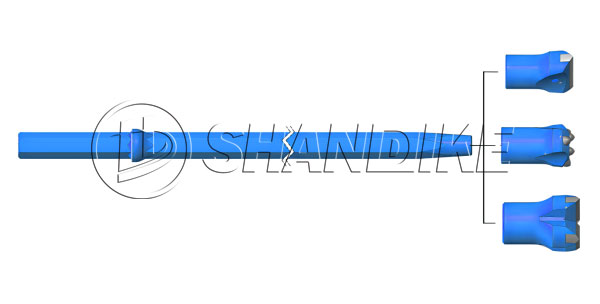

Rock drill rods are specialized tools utilized in mining, construction, geological exploration, and various other industries in conjunction with rock drills and drill bits. Their primary function is to transmit the impact force and torque generated by the rock drill to the drill bit, enabling the bit to penetrate and fragment rock to create boreholes.

Types of Rock Drill Rods

Rock drill rods are categorized into various types based on their specific applications, including top hammer drill rods, down-the-hole (DTH) drill rods, and tapered drill rods.

Differences Between Types of Rock Drill Rods

SHANDIKE: A Specialized Manufacturer of Drilling Tools

SHANDIKE is a specialized manufacturer of drilling tools, offering a range of rock drill rods with various specifications. If you are interested in our products, please contact us for more information.

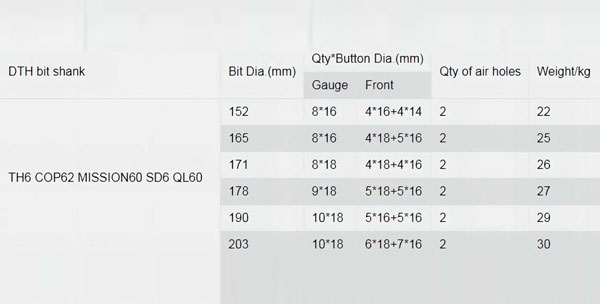

DTH (Down The Hole) Bits, also known as down the hole drill bits, are important tools used for rock drilling and drilling. DHD360, COP64, QL60, SD6, and Mission60 are different models or specifications of down the hole drill bits, usually equipped with corresponding drill rods (Shank) for connecting the drilling rig and drill bit, transmitting torque and impact force.

Product Features

High wind pressure adaptability: These down the hole drill bits are typically designed to work in high wind pressure environments, capable of withstanding significant impact forces, ensuring drilling efficiency and quality.

Multiple specifications are available: DHD360, COP64, QL60, SD6, Mission60 and other models represent different drill bit specifications and sizes, suitable for drilling needs of different apertures and depths.

High quality material manufacturing:

1. High quality forging technology improves the fatigue strength of the drill bit body.

2. High quality hard alloy and suitable size can ensure the stability of the hard alloy life of the drill bit.

3. Easy to replace and maintain: The connection between the drill bit and drill rod is designed reasonably, making it easy to replace and maintain, reducing downtime and maintenance costs.

3、 Application Fields

These down the hole drill bits are widely used in mining, oil exploration, water well drilling, foundation engineering construction and other fields. They can efficiently penetrate rocks and soil, providing necessary drilling support for various engineering projects.

Three Kind Of Bit Face And Two Kind Of Button Shapes Are Available

Flat Face

Application: Hard and abrasive rock formation.

Typical formation: Granite, hard limestone, basalt.

Concave Face

Application: Medium hard to hard formations. Less abrasive, fractured formations. Excellent control for hole deviation.

Typical formation: Granite, hard limestone, basalt.

Convex Face

Application: Soft to medium hard rock. Non abrasive formation. High penetration rate.

Typical formation: Limestone, hard limestone, shale.

Features

1. Excellent insetting technology ensures that the carbides will not drop out from the bit body.

2. Advanced heat treatment equipment and technology to ensure the stability of the bit body performance.

3.Special bit surface design, structure design and specific processing technology are adopted to ensure the service life of DTH bit for different rock formation.

We can also supply other size bits with different shanks. If you need more information, please contact our sales for details.

3.5”: DHD3.5, IR3.5, BR33

4”: DHD340, COP44, QLX40, TD40, SD4, MISSION40

5”: DHD350, COP54, QL50, SD5, MISSION50

6’: DHD360, COP64, QL60, SD6, MISSION60

8”: DHD380, QL80, SD8, MISSION80

10”: SD10, NUMA100

Large Diameter DTH BITS

The large diameter bits are mainly used in three applications: embedded prefabrication pile, long spiral pile and large diameter end bearing pile.

We can supply large diameter bits with different size and shanks:

12”: DHD112, SD12, NUMA120, NUMA125

14”: NUMA125

18’: NUMA180

24”: NUMA240

Large Diameter DTH Bits Features

Wide applied for complex rock formation like caves, pebbles, fissures etc;

Drilling through hard rocks with high penetration rate;

Low air consumption.

QSAAA Taper Drill Rods are high-quality rock drilling tools.

| 22mm(7/8″)Tapered drill rods | L | Taper Degree | Weight (kg) | |

| mm | foot/inch | |||

| H22×108 Shank | 500 | 1′ 5/8″ | 7o | 1.5 |

| 800 | 2′7 1/2″ | 2.4 | ||

| 1000 | 3′3 3/8″ | 3 | ||

| 1200 | 3′11 1/4″ | 3.6 | ||

| 1500 | 4′ 11″ | 4.5 | ||

| 1800 | 5′10 7/8″ | 5.5 | ||

| 2000 | 6′6 3/4″ | 6.1 | ||

| 2200 | 7′2 5/8″ | 6.7 | ||

| 2500 | 8′2 3/8″ | 7.6 | ||

| 3000 | 9′10 1/8″ | 9.1 | ||

| 3500 | 11′5 3/4″ | 10.6 | ||

| 4000 | 13′1 1/2″ | 12.1 | ||

| 4500 | 14′9 1/8″ | 13.6 | ||

| 5000 | 16′4 5/8″ | 15.1 | ||

| 6000 | 19′8 1/4″ | 18.2 | ||

| 7000 | 22′11 5/8″ | 21.2 | ||

| 8000 | 26′ 3″ | 24.2 | ||

| H22×108 Shank | 800 | 2′7 1/2″ | 12o | 2.4 |

| 1200 | 3′11 1/4″ | 3.6 | ||

| 1600 | 5′ 3″ | 4.9 | ||

| 2200 | 7′2 5/8″ | 6.7 | ||

| 2400 | 7′10 1/2″ | 7.3 | ||

| 3200 | 10′ 6″ | 9.7 | ||

| H22×108 Shank | 1800 | 5′10 7/8″ | 7o | 5.5 |

| 2000 | 6′6 3/4″ | 6.1 | ||

| 2500 | 8′2 3/8″ | 7.6 | ||

| 3000 | 9′10 1/8″ | 9.1 | ||

| 3500 | 11′5 3/4″ | 10.6 | ||

| 4000 | 13′1 1/2″ | 12.1 | ||

| 5000 | 16′4 5/8″ | 15.1 | ||

If you need Tape Rods QSAAA, please contact SHANDIKE Company. We are one of the largest QSAAA DRILL RODS manufacturers

Pneumatic Rock Drill Rods are an important component in the field of pneumatic tools, mainly used for drilling operations on hard materials such as rocks.

1、 Definition and purpose

The drill rod of a pneumatic rock drill is a key component of the pneumatic rock drill. It uses compressed air as a power source to push the drill rod and drill bit into the rock through the impact and rotation of the pneumatic rock drill, thereby achieving the purpose of drilling. Pneumatic rock drills are widely used in mining, tunnel excavation, rock exploration, water conservancy and hydropower engineering and other fields.

2、 Structure and Characteristics

Structure: The drill rod of a pneumatic rock drill usually consists of three parts: the rod body, the joint, and the drill bit. The rod body is the main part of the drill rod, usually made of high-strength alloy steel to withstand the impact and torsional forces during drilling. The joint is used to connect the drill rod and the rock drill, ensuring that the drill rod can stably transmit power. The drill bit is the working part of the drill rod, used for directly crushing rocks.

characteristic:

High strength: The drill rod needs to withstand the huge impact and torsional force during the drilling process, so it must have high strength.

Wear resistance: The drill rod will rub against the rock during the drilling process, so it must have good wear resistance.

Easy to replace: In order to facilitate maintenance and replacement, drill rods are usually designed with modularity, which allows for easy disassembly and replacement of drill bits.

3、 Working principle

The working principle of the drill rod of the pneumatic rock drill is based on the working principle of the pneumatic rock drill. When compressed air enters the rock drill, it will push the piston to perform reciprocating motion, thereby generating impact force and rotational force. These forces are transmitted to the drill bit through the drill rod, causing the drill bit to perform impact and rotation drilling in the rock.

4、 Usage and maintenance

Usage: When using the drill rod of a pneumatic rock drill, the following points should be noted:

Ensure that the connection between the rock drill and the drill rod is firm and reliable.

Select appropriate drill bits and rods based on the hardness of the rock and the diameter of the borehole.

Proper impact force and rotation speed should be maintained during the drilling process.

Maintenance: In order to extend the service life of the drill rod of the pneumatic rock drill, regular maintenance and upkeep are required. Specifically, it includes:

Regularly inspect the wear of drill pipes and replace severely worn ones in a timely manner.

Keep the drill rod and rock drill clean to prevent dust and debris from entering.

Lubricate the drill rod to reduce friction and wear.

5、 Development Trends

With the advancement of technology and the development of engineering fields, the drill rods of pneumatic rock drills are constantly improving and innovating. Future development trends may include:

Material innovation: Using higher strength and more wear-resistant materials to manufacture drill rods to improve their service life and performance.

Intelligent design: By integrating sensors and intelligent control systems, real-time monitoring and intelligent control of the working status of drill pipes can be achieved.

Modular design: Further optimize the modular design of the drill pipe to make it easier to disassemble, replace, and maintain.

In summary, the drill rod of a pneumatic rock drill is an important component in the field of pneumatic tools, with broad application prospects and development potential. With the continuous advancement of technology and the continuous development of engineering fields, the performance and intelligence level of pneumatic rock drilling drill rods will continue to improve, providing more efficient and reliable drilling solutions for various engineering fields.

Pneumatic rock drill rod models

| 22mm(7/8″)Tapered drill rods | L | Taper Degree | Weight (kg) | |

| mm | foot/inch | |||

| H22×108 Shank | 500 | 1′5/8″ | 7o | 1.5 |

| 800 | 2′7 1/2″ | 2.4 | ||

| 1000 | 3′3 3/8″ | 3 | ||

| 1200 | 3′11 1/4″ | 3.6 | ||

| 1500 | 4′11″ | 4.5 | ||

| 1800 | 5′10 7/8″ | 5.5 | ||

| 2000 | 6′6 3/4″ | 6.1 | ||

| 2200 | 7′2 5/8″ | 6.7 | ||

| 2500 | 8′2 3/8″ | 7.6 | ||

| 3000 | 9′10 1/8″ | 9.1 | ||

| 3500 | 11′5 3/4″ | 10.6 | ||

| 4000 | 13′1 1/2″ | 12.1 | ||

| 4500 | 14′9 1/8″ | 13.6 | ||

| 5000 | 16′4 5/8″ | 15.1 | ||

| 6000 | 19′8 1/4″ | 18.2 | ||

| 7000 | 22′11 5/8″ | 21.2 | ||

| 8000 | 26′3″ | 24.2 | ||

| H22×108 Shank | 800 | 2′7 1/2″ | 12o | 2.4 |

| 1200 | 3′11 1/4″ | 3.6 | ||

| 1600 | 5′3″ | 4.9 | ||

| 2200 | 7′2 5/8″ | 6.7 | ||

| 2400 | 7′10 1/2″ | 7.3 | ||

| 3200 | 10′6″ | 9.7 | ||

| H22×108 Shank | 1800 | 5′10 7/8″ | 7o | 5.5 |

| 2000 | 6′6 3/4″ | 6.1 | ||

| 2500 | 8′2 3/8″ | 7.6 | ||

| 3000 | 9′10 1/8″ | 9.1 | ||

| 3500 | 11′5 3/4″ | 10.6 | ||

| 4000 | 13′1 1/2″ | 12.1 | ||

| 5000 | 16′4 5/8″ | 15.1 | ||

| 25mm(1″)Tapered drill rods | L | Taper Degree | Weight (kg) | |

| mm | foot/inch | |||

| H25×108 Shank | 1500 | 4′11″ | 7o | 5.9 |

| 1600 | 5′3″ | 6.3 | ||

| 1800 | 5′10 7/8″ | 7.1 | ||

| 2000 | 6′6 3/4″ | 7.9 | ||

| 2500 | 8′2 3/8″ | 9.9 | ||

| 3000 | 9′10 1/8″ | 11.9 | ||

| 4000 | 13′1 1/2″ | 15.8 | ||

| H25×159 Shank | 4200 | 13′9 3/8″ | 7o | 16.6 |

| 4700 | 14′10″ | 18.6 | ||

| 5000 | 16′4 5/8″ | 19.8 | ||

| 5500 | 18′1/2″ | 21.7 | ||

Shandike, a manufacturer of rock drilling tools, produces hexagon-shaped drill steel for rock drill bits.

To enhance strength at the rock drill end and accommodate larger diameter and shank adapters, it is common to increase the drive end of drifting drill steel. Drill steel is available in various standard lengths to match the drill feeds of multiple drifting jumbos. Since the coupling does not enter the hole, a bit diameter closer to the steel diameter can be utilized, which improves flushing and hole accuracy.

Shandike offers drill bits, couplings, shank rods, and tunnel rods in lengths ranging from 2440mm to 6435mm (8′-21′) with R25, R28, and R35 bit end threads and standard shank end thread types. The hexagon body sizes range from H25 to H35, and round rods are available with a diameter of 39mm. Male/Female tunnelling rods are also available in 35mm hexagon and 39mm round.

Hexagon drifting drill rods with a hex size of 35 have several advantages:

The cross-sectional dimension of the material is measured across the flat, providing increased rigidity and weight.

The cross-sections transfer energy more efficiently and reduce annuls in the drill hole, enhancing flushing.

The smaller space combined with the corners of the steel creates turbulence in the hole, keeping heavier cuttings moving, especially in horizontal holes.

The rigidity of the cross-section allows for the use of a larger thread.

Rope threads, such as R32, have a low pitch (12.7mm) and a small angle of profile. They range in size from 22mm to 38mm and have good wear properties but poor uncoupling. They are ideal for single-pass or short-hole drilling applications, such as underground tunneling, that require infrequent uncoupling. Rope threads larger than R32 are not recommended for extension drilling with high-powered drills due to difficulty in uncoupling.

HM or “T” threads, such as T38, have a larger pitch and a larger angle of profile than rope threads. They come in sizes 38mm, 45mm, and 51mm and have excellent wear properties and good coupling qualities. They are ideal for extension drilling with multiple steel, compatible with heavy high-torque rock drills for surface and underground applications.

The SHANDIKE line of 6” Down-The-Hole (DTH) hammers leverages proven technology to offer exceptional performance at the highest levels compared to other drills available in the market. These tools are versatile and highly suitable for a wide array of drilling applications, encompassing residential geothermal installations, production quarry drilling, seismic exploration drilling, and small-scale construction drilling projects.

Within the SHANDIKE range of 6” hammers, customers can choose from several popular shank options: the QL60 shank, which is widely used and highly regarded; the DHD 360 shank, known for its robustness and reliability; and the SD6 shank, another trusted variant.

SHANDIKE has incorporated patented features into these hammers to maximize energy output while simultaneously minimizing the need for maintenance and service. By reducing the number of internal components, the complexity of service and maintenance requirements is greatly decreased. The valveless, high-frequency design of these hammers ensures a smooth and consistent operation, which further enhances their reliability and durability.

Each hammer features a hardened wear sleeve that provides superior wear resistance, even in the most abrasive and demanding drilling conditions. The multi-start threads on both the backhead and chuck make coupling and uncoupling of the hammer quick and easy, saving time and effort on the job site.

Additionally, the unique internal mount system eliminates the need for wear shims and special assembly tools, simplifying the installation and setup process. All critical internal components have undergone heat treatment under strict control, ensuring they are resilient and capable of withstanding the stresses and rigors of constant use, thereby maximizing the tool’s overall longevity and service life.

In summary, the SHANDIKE range of 6” DTH hammers combines proven technology, versatility, reliability, and advanced design features to deliver outstanding performance across a variety of drilling applications.

| Hammer | BR2A | DHD3.5 | HK4D | HD45 | HQL4A | HQL50 | HK5Q | HD55 | HQL60 | HQL6A | HQL80 | HD85 | HK9Q | HSD10 | HSD12 | HK12Y | N125-R |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Recommended bit size, mm | 76 | 92-105 | 112-127 | 140-152 | 165-178 | 203-229 | 216-229 | 245-305 | 305-445 | 305-350 | 305-445 | ||||||

| Bit Shank | BR2A | DHD3.5 | DHD340A | QL40 | QL50 | DHD350 | QL60 | QL80 | DHD380 | QL80 | SD10 | SD12 | HY12 | NUMA125R | |||

| External diameter, mm | 63 | 82 | 100 | 100 | 101 | 126.5 | 127.5 | 126.5 | 148 | 146 | 185 | 185 | 203 | 225 | 275 | 275 | 275 |

| Length excl. thread, mm (Less bit) | 837 | 855 | 915 | 1032.5 | 1057 | 1147 | 935 | 1167 | 1121 | 1182 | 1471 | 1487 | 1345 | 1413 | 1680 | 1590 | 1812 |

| Hammer weight, kg (Less bit) | 14.1 | 25 | 37.5 | 40.6 | 41 | 71.6 | 67.6 | 77.2 | 105 | 105 | 203 | 206 | 228 | 303 | 526 | 510.2 | 546 |

| Package case size | (L)910 (W)90 (H)120 | (L)1200 (W)110 (H)140 | (L)1010 (W)130 (H)160 | (L)1080 (W)125 (H)134 | (L)1150 (W)130 (H)160 | (L)1290 (W)150 (H)175 | (L)1100 (W)155 (H)180 | (L)1290 (W)150 (H)175 | (L)1270 (W)170 (H)200 | (L)1260 (W)180 (H)200 | (L)1440 (W)230 (H)270 | (L)1560 (W)230 (H)270 | (L)1500 (W)240 (H)280 | (L)1620 (W)275 (H)290 | (L)1880 (W)320 (H)320 | (L)1665 (W)320 (H)360 | (L)1880 (W)310 (H)310 |

| Top Sub thread | RD50 | 2-3/8″ API REG | 3-1/2″ API REG | 4-1/2″ API REG | 6-5/8″ API REG | 6-5/8″ API REG 7-5/8″ API REG | 6-5/8″ API REG | ||||||||||

| Working Pressure, PSI | 80-170 | 150-250 | 200-300 | 250-350 | 300-350 | 300-380 | 300-380 | 150-350 | 200-350 | ||||||||

| Air consumption, CFM | 250-350 | 300-400 | 500-700 | 500-800 | 600-900 | 950-1200 | 950-1200 | 1000-1800 | 1200-1500 | 800-1800 | |||||||

| Piston diameter, mm | 42.7 | 65 | 82 | 80 | 80 | 104 | 102 | 100 | 122 | 121 | 150 | 150 | 165 | 185 | 225 | ||

| Piston weight, kg | 1.7 | 5.1 | 9.2 | 9 | 9 | 17 | 17 | 16 | 24 | 24 | 38 | 42 | 50 | 68 | 110 | 111 | 111 |

| Wrench flat, mm | L47 W50 | L57 W35 | L74.5 W45 | L64 W40 | NO wrench flat | L89 W60 | L88 W50 | L89 W60 | L101 W65 | L101 W60 | L128 W70 | L140 W70 | L128 W70 | L140 W70 | L140 W70 | L140 W70 | L140 L70 |

| Feed force, kN | 2~6 | 3~8 | 5~15 | 6~25 | 7~20 | 10~25 | 15~30 | 20~35 | |||||||||

| Rotation speed, r/min | 30-70 | 3-90 | 25-80 | 20-70 | 25-60 | 20-60 | 15-35 | ||||||||||

| Drilling conditions and project specifications may require larger air package to be used | |||||||||||||||||

DTH (Down-The-Hole) hammers are specialized tools used for drilling in hard rock formations. When it comes to water well drilling, using the right equipment is crucial to ensure efficiency and effectiveness. Here are some key points to consider about DTH hammers for hard rock water well drilling:

1. Design and Durability: DTH hammers designed for hard rock drilling are built to withstand the intense conditions. They typically feature robust construction and high-quality materials to ensure longevity and reliability.

2. Impact Energy and Frequency: Hard rock requires significant impact energy to break through. DTH hammers are designed to deliver high impact energy and frequency to efficiently drill through tough rock formations.

3. Bit Diameter and Compatibility: The bit diameter of the DTH hammer should match the requirements of the water well being drilled. For a 6-inch diameter well, you would need a DTH hammer with a compatible bit size.

4. Air Pressure and Compressor Requirements: DTH drilling relies on compressed air to power the hammer. It’s important to have an air compressor with sufficient capacity to meet the air pressure requirements of the DTH hammer.

5. Maintenance and Serviceability: Regular maintenance is essential for DTH hammers to ensure they operate efficiently. Look for designs that are easy to service and have readily available replacement parts.

6. Customization Options: Different hard rock formations may require different drilling strategies. Having the ability to customize the DTH hammer with various bits and accessories can be beneficial.

7. Supplier Reputation and Support: Choosing a reputable supplier with a strong after-sales support network can make a significant difference in the long-term performance and maintenance of your DTH hammer.

When selecting a DTH hammer for hard rock water well drilling, it’s important to consider these factors to ensure you choose the right tool for the job. Consulting with a specialist or supplier with experience in your specific application can also be helpful in making an informed decision.

Information on T38, T45, and T51 rock drill rods coupling sleeves. These coupling sleeves are used to connect rock drill rods to extend their length, and are suitable for fields such as mining, quarrying, tunnel construction, and construction.

Product Description

T38, T45, and T51 rock drill rods coupling sleeves are connectors designed specifically for rock drill rods, used to extend the length of the drill rods. These sleeves are typically made of high-strength alloy steel and undergo CNC machining and heat treatment to ensure reliable connections and durability.

main features

High strength material: Made of high-quality alloy steel, it has high wear resistance and strength.

Precision machining: Through CNC machining, dimensional accuracy and surface smoothness are ensured.

Heat treatment: Through strict heat treatment processes, the hardness and toughness of the material have been improved.

Wide applicability: Suitable for T38, T45, and T51 rock drill rods, widely used in mining, quarrying, tunnel construction, and construction fields.

Application scenarios

Mining: Used for drilling operations in underground and open-pit mines.

Quarry: Used for drilling operations in stone mining.

Tunnel construction: used for drilling and blasting operations in tunnel excavation.

Architecture: Used for drilling operations in foundation engineering and pile foundation construction.

Supplier Information

These products are provided by multiple suppliers, and you can find relevant supplier information on the Alibaba website. Suppliers typically offer customized services and can provide suitable products based on your specific needs.

ordering information

Minimum order quantity: usually 1 piece, but the specific quantity may vary depending on the supplier.

Price range: Prices vary depending on the supplier, materials, processing techniques, and order quantity, generally ranging from $7 to $120 per piece.

Delivery time: usually 7 to 20 days, depending on the order quantity and supplier’s production capacity.

The optimal operating temperature range for DTH (Down The Hole) drill bits varies depending on specific drilling conditions and drill bit types. DTH drill bits are commonly used for rock excavation and mining operations, and their working temperature is affected by factors such as rock temperature, drilling speed, lubrication and cooling systems.

In general drilling applications, it is recommended to maintain the working temperature of the DTH drill bit within a low range to ensure its durability and efficiency. Here are several key factors and suggestions:

Cooling system: Use water or other coolant to lower the temperature of the drill bit and prevent overheating. Coolant can help remove the heat generated during the drilling process and extend the service life of the drill bit.

Lubrication: Proper lubrication can reduce the friction between the drill bit and the rock, lower the temperature, and improve the efficiency of the drill bit.

Drilling speed and load: Excessive drilling speed and load can cause the temperature of the drill bit to rise rapidly, affecting its performance and lifespan. Reasonable drilling parameter settings help maintain appropriate working temperatures.

Drill bit material: Different materials of DTH drill bits have different temperature tolerances. For example, diamond drill bits can typically operate at higher temperatures, but still require proper cooling and lubrication.

The optimal working temperature range for DTH drill bits is usually at lower temperatures. Through effective cooling and lubrication systems, as well as reasonable drilling parameter settings, the optimal working state of the drill bit can be maintained. The specific temperature range should be determined based on the actual drilling conditions and the recommendations of the drill bit manufacturer.

DTH (Down The Hole) drill bits are mainly used for mining, construction, and other heavy drilling operations. Due to its harsh working environment, regular maintenance of lubrication and cooling systems is crucial. The following are the maintenance methods for the lubrication and cooling system of the DTH drill bit:

By using the above methods, the lubrication and cooling system of the DTH drill bit can be effectively maintained, extending the service life of the equipment and improving work efficiency.

DTH (Down-The-Hole) drill bits are commonly used in industries such as mining, construction, and geological exploration. Improving the service life of DTH drill bits can be achieved through the following aspects:

By implementing the above measures, the service life of DTH drill bits can be significantly increased, reducing drilling costs and improving work efficiency.

Choosing the appropriate DTH (Down-The-Hole) drill bit involves considering multiple factors to ensure optimal performance and the longest lifespan for the specific application. Here are some key steps and considerations in selecting the right DTH drill bit:

By comprehensively considering these factors, you can select the most suitable DTH drill bit to enhance drilling efficiency and reduce costs.

If you need to purchase DTH drill bits, please choose Shandike company, the quality and price are both suitable

DTH (Down-The-Hole) drill pipe is a specialized type of drill pipe used in DTH drilling applications. It is designed to withstand the high impact forces generated by the DTH hammer and to provide efficient energy transfer from the hammer to the drill bit. Here are some key points about DTH drill pipes:

If you need to purchase DTH drill pipes, please choose Shandike company, the quality and price are both suitable

Reverse Circulation (RC) Drilling Rods: Introduction, Characteristics, Applications, and Comparative Analysis

Reverse Circulation (RC) Drilling Rods, also known as double-wall or double-layer drill rods, offer a unique and efficient drilling solution. Here’s a detailed introduction to their structural characteristics, functions, applications, specifications, selection considerations, and a comparative analysis with normal circulation drilling rods.

Structural Characteristics

RC drill rods feature a double-layer structure comprising an inner pipe and an outer pipe. This design creates an annular gap, which serves as a passage for pumping flushing media (like water or mud) to the hole bottom during drilling operations. The inner and outer pipes are connected using specific methods to ensure effective transmission of torque and pressure. The outer tube typically employs threaded connections, while the inner tube often uses a plug-in design with a sealing device at the connection point.

Functions and Applications

The primary function of RC drill rods is to deliver flushing media to the hole bottom via the annular gap. This media cools the drill bit, carries away drilling debris, and maintains hole wall stability. Simultaneously, the inner tube acts as a return conduit for the flushing media and drill cuttings, transporting them back to the surface. RC drill rods are extensively used in geological and mineral exploration, as well as hydrological well drilling. Their efficient and stable drilling performance makes them indispensable for boreholes with diameters of 84mm and 93mm, reaching depths of up to 300m.

Specifications and Parameters

RC drill rods come with varying specifications and parameters depending on the manufacturer and application. Common specifications include outer tube outer diameters (O.D.) ranging from 88.9mm, 101.7mm, to 114.3mm, inner tube inner diameters (I.D.) varying based on the outer diameter and wall thickness (commonly 38.1mm, 50.8mm, and 63.5mm), standardized wall thicknesses for both inner and outer pipes, and customizable lengths to fit drilling requirements (common lengths include 3m, 4.5m, and 6m).

Selection and Purchase

When choosing and purchasing RC drill rods, consider factors such as drilling requirements (including wellbore diameter, drilling depth, and geological conditions), manufacturer reputation (opt for manufacturers with a solid reputation and extensive experience), and price and cost-effectiveness (ensure quality while considering the price factor).

Comparative Analysis with Normal Circulation Drilling Rods

In summary, Reverse Circulation RC Drilling Rods hold significant application potential and market demand in geological and mineral exploration. When selecting and purchasing, comprehensive consideration of factors like drilling needs, manufacturer reputation, and price is crucial to ensure the drill rods meet actual operational requirements.

Rock drilling thread extension steel bars encompass various types such as extension rods, MF rods, light extension drill rods, drifter rods, and shank adapter drill rods. These can also be termed threaded drill rods or threaded pipes, featuring either single-ended or double-ended threading, and coming in hollow round or hollow hexagonal shapes. They constitute a vital component of threaded connection drilling tools and equipment. Connected to top hammer rock drill rigs via shank adapters and couplings, and to drill bits via threads on the other end, these threaded rods can be linked with other drill rods to form a complete set of threaded connection drilling tools. They can be paired with a single shank adapter and drill bit, or multiple adapters and bits, and are suitable for shallow holes and small-diameter rock drilling. With a wide range of applications, high drilling speeds, minimal impact energy transmission loss, and enhanced drilling efficiency, they facilitate drilling mechanization and improve drilling conditions. Consequently, thread extension drill rods occupy a significant proportion in the overall drilling industry.

Rock drilling thread extension steel bars must possess high fatigue strength, elasticity, rigidity, and toughness, although strength and toughness are often in conflict. The threads at both ends of the rods are crucial for forming a complete set of drilling tools. Material properties can only be fully utilized after heat treatment, making material selection and heat treatment processes equally important.

M/F extension rods, a type of round or hexagonal threaded drill rod with one end as an internal thread and the other as an external thread, are often referred to as MF drill rods internationally. They facilitate quick rod connections with coupling sleeves, reducing the weight and length of the complete drilling tools, shortening threaded connections, and minimizing thread joint impact energy loss. This enhances ease of loading and unloading, and significantly increases drilling speed and efficiency.

Specifications include:

In mining operations, GT60 MF drill rods are widely used for tunnel excavation, ore mining, and other tasks. Similarly, in geological exploration, geotechnical engineering, and other fields, GT60 MF drill pipes are commonly employed for rock drilling operations.

January 11, 2024

January 11, 2024