In the development of Australia’s vast mineral resources, the choice of drilling equipment directly impacts project efficiency and cost control. R32 drill pipe, with its superior performance and durability, is becoming an increasingly important focus for mining companies. However, in the face of constantly fluctuating market conditions, obtaining accurate R32 drill pipe price information has become a common challenge for many enterprises.

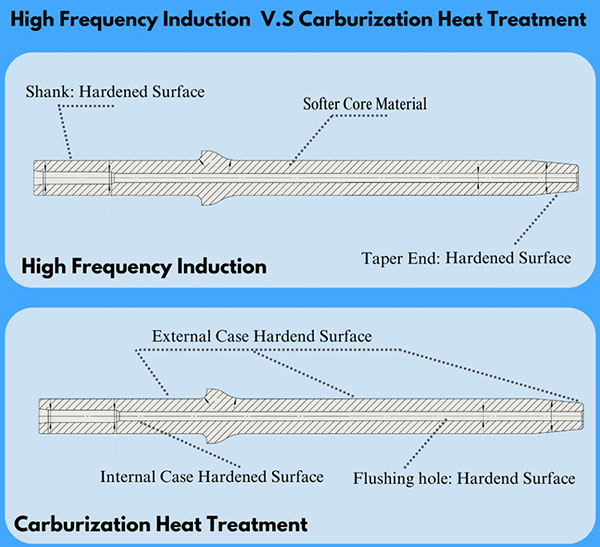

R32 drill pipe is made of high-quality alloy steel and undergoes a special heat treatment process, giving it excellent torque resistance and wear resistance, making it particularly suitable for Australia’s diverse geological conditions. From iron ore mines in Western Australia to coal mines in Queensland, R32 drill pipe demonstrates stable drilling performance and a longer service life in various complex formations.

The advantages of this drill pipe are not only reflected in its superior physical properties, but also in the overall economic benefits it can bring to the project—reducing replacement frequency, reducing downtime, and improving drilling efficiency. These factors work together to ultimately optimize the total project cost.

The price of R32 drill pipe in the Australian market is not fixed but is influenced by a variety of factors:

Raw material cost fluctuations: Changes in global steel market prices directly affect drill pipe production costs.

Transportation and logistics costs: International shipping prices, domestic shipping distances and methods within Australia.

Specifications and customization requirements: Drill pipes of different lengths, wall thicknesses, and special treatments have significant price differences.

Purchasing scale: Bulk orders usually result in more competitive unit prices.

Market supply and demand: Mining cycle fluctuations affect equipment demand and prices.

Accurate Quote: Why Professional Consultation is Essential?

Obtaining an accurate R32 drill pipe quote involves much more than just a number; it requires comprehensive consideration:

Project Matching Analysis: Your specific geological conditions, drilling depth, and strength requirements.

Full Lifecycle Cost Assessment: Including initial procurement, operation, maintenance, and replacement costs.

Supply Chain Stability: Delivery time, inventory status, and the possibility of long-term cooperation.

Additional Service Value: Technical support, after-sales service, and warranty terms.

Contact Luoyang Shandi Ke: Get Your Customized Quote

You’re comparing prices for 38mm hex extension drill rods. That’s natural. Cost is always a key factor when procuring rock drilling tools.But as a professional, you know better than anyone: The lowest “sticker” price often comes with the highest total cost of ownership.The true value of a 38mm Hex Extension Rod is never reflected on the purchase invoice—it’s embedded in every single drilling cycle.

What does a hex connection with micron-level precision mean? It means zero-clearance power transmission. It means every impact is fully delivered to the rock, not wasted in inefficient collisions between the rod and the drill. It translates to faster penetration rates, reduced machine vibration, and extended equipment life. Our 38mm rods are forged from a specific micro-alloy steel formula, engineered to balance extreme hardness with fatigue resistance. This prevents premature brittle fractures or excessive wear, extending your work cycles in meters drilled, not hours lost to downtime.

Consider this: during a critical project phase, what is the real cost of replacing a failed rod due to wear or breakage? It’s not just the cost of a new rod. It’s the cost of machine downtime, labor, and delays cascading across the entire worksite. Our goal is not to be the cheapest line item on your quote, but to be the most reliable and stable multiplier in your productivity equation. Through optimized heat treatment and surface hardening technologies, our rods maintain their integrity in the toughest formations, minimizing change-out frequency—that’s the most fundamental protection for your bottom line.

Every rock drill has its unique “pulse.” Our 38mm hex extension rods are not just made to dimensional standards; they are designed as a precision-engineered extension of your rig’s power train. We focus on torque transmission efficiency, stress distribution, and wave impedance matching. This ensures the rod works in synergy with your equipment—whether it’s Sandvik, Atlas Copco, or other leading brands—to deliver 100% of its intended performance while protecting the valuable drill head from damaging recoil.

So, when you evaluate the “38mm Hex Extension Rod Price,” you are really assessing a critical investment for your project’s success.

We invite you to make a more meaningful comparison: look beyond the price per rod, and calculate the cost per drilled meter.

Request our detailed Technical Specification & TCO Analysis Portfolio to see how our 38mm hex extension rods optimize your total cost of ownership in real-world conditions. Let us respond to your price inquiry with a professional engineering solution.

— Engineered for Value, Not Just Supplied as a Product —

As a global mining powerhouse, Australia maintains strong demand for high-quality exploration tools like T51 drill rods. This article analyzes their market price and core value to support informed purchasing decisions.

Advantages of T51 Drill Rods

As an internationally standardized specification, T51 rods are known for high-strength alloy steel, reliable tapered thread connections, and strong adaptability to complex geology, making them a dependable choice for hard rock drilling in Australia.

Key Factors Influencing Price in Australia

Global Steel Costs: Fluctuations in raw material prices directly impact final pricing.

Supply Source: Price variations exist between imported brands (from the US, Europe, China) and locally manufactured products. Imports may offer advanced technology, while local supply often means faster logistics.

Product Specifications: Material grade, length, heat treatment, and special coatings are primary price determinants.

Procurement & Logistics: Bulk purchases typically secure discounts, while urgent orders to remote sites incur higher costs.

Current Market Price Range (Reference)

Standard Grade: Approximately AUD 80 – 120 per meter

Enhanced Grade: Approximately AUD 120 – 180 per meter

High-Strength/Special Grade: AUD 180+ per meter

(Note: Prices are subject to market changes. Rental options are also widely available.)

How to Choose a Supplier in Australia?

Reputation & Local Support: Prefer suppliers with local warehouses and technical teams.

Certifications & Compliance: Ensure products meet Australian safety standards.

After-Sales Service: Evaluate repair, replacement, and technical support capabilities.

Total Cost of Ownership: Consider the overall cost including product price, shipping, and duties.

Primary Applications

T51 rods are widely used in iron ore and gold exploration in Western Australia, nationwide geological surveys, and geotechnical investigations for major infrastructure projects. Their performance directly impacts operational efficiency and data accuracy.

Purchasing Recommendations

We recommend conducting regular market comparisons, building long-term relationships with reliable suppliers, and selecting the appropriate product grade based on specific project needs, focusing on the total lifecycle cost.

R32 drill rods, as core tools in modern tunnel excavation and geological exploration, play a pivotal role in mining, water conservancy, transportation construction, and other fields with their exceptional performance and reliable quality. Designed specifically for medium-to-deep hole rock drilling, these rods efficiently transmit impact energy, ensuring stable and efficient drilling operations.

High-Strength Alloy Material

R32 drill rods are manufactured from premium alloy steel and undergo special heat treatment processes, providing high fatigue resistance and wear resistance. The internal and external threads are precision-machined to ensure tight connections, effectively preventing loosening or breakage during drilling.

Optimized Energy Transfer Efficiency

The uniquely designed rod structure minimizes energy loss, ensuring that the impact force from hydraulic or pneumatic rock drills is efficiently transmitted to the drill bit. This significantly increases drilling speed while reducing energy consumption.

Multiple Length Specifications

To accommodate drilling needs at different depths and under various working conditions, R32 drill rods are available in multiple length specifications. Please note that product pricing varies depending on the length and specifications. We can provide the most economical configuration based on your specific requirements.

Excellent Compatibility

R32 drill rods are fully compatible with mainstream R32 threaded drill bits on the market and can also be paired with various models of rock drilling equipment, offering flexible configuration options.

Choosing Rod Length Based on Drilling Depth

Considering Rock Formation Conditions

Matching Equipment Power

Ensure the strength specifications of the selected drill rods match the output power of your rock drilling equipment to prevent premature wear or equipment overload due to mismatched power.

Connection Method Considerations

Choose between integral or modular drill rods based on operational frequency. For high-frequency operations, integral rods are recommended to reduce wear at connection points. For multi-condition operations, modular rods offer greater adaptability.

R32 drill rods, with their reliable performance and flexible configurations, meet drilling requirements under various complex geological conditions. Our professional technical team can provide tailored selection advice to help you choose the most suitable drill rod configuration based on specific project needs, maximizing operational efficiency and cost-effectiveness.

For more technical details or personalized selection solutions, please feel free to contact our technical advisory team.

T51 drill rods, as core tools in deep-hole drilling operations, have become the preferred choice in fields such as mining, geological exploration, hydrogeological engineering, and geothermal development due to their exceptional strength, wear resistance, and fatigue resistance. This article provides an in-depth analysis of the technical characteristics, application scenarios, selection considerations, and maintenance recommendations for T51 drill rods. It aims to assist clients in selecting the most suitable drilling solution based on actual working conditions, thereby maximizing efficiency and optimizing costs.

The YT28 pneumatic rock drill is a well-known piece of equipment in Zimbabwe’s mining, construction, and infrastructure sectors. It is favored for its robustness, simple design, and ability to handle complex rock conditions. However, for anyone looking to purchase this equipment in Zimbabwe, a straightforward question is: “How much does it cost?”

The answer is: In Zimbabwe, a brand new YT28 rock drill generally costs between US$800 and US$3,500 (or the equivalent in Zimbabwean dollars). However, this price range varies considerably, as different brands have different prices.

YT28 Rock Drill (Air Leg Type) Product Introduction

The YT28 rock drill is a pneumatic (air-powered) device widely used in rock drilling operations. It is a lightweight, efficient, medium-to-high-frequency rock drill, typically paired with an automatic telescopic air leg (such as the FY200B model) to form a hand-held air leg rock drill unit. It is a classic tool for drilling horizontal or inclined boreholes in medium-hard to hard rock.

Its core power comes from compressed air. When high-pressure air passes through the precise air distribution device inside the equipment, it drives the piston to perform high-speed reciprocating motion within the cylinder. The piston periodically impacts the shank rod (drill steel) at the rear. The impact energy is transmitted through the drill steel to the bit at the front, thereby breaking the rock. Simultaneously, during the intervals between impacts, another mechanism rotates the drill steel a certain angle, creating a new position for the next impact, enabling continuous drilling.

This is a high-strength drill rod designed for percussive rock drilling. Its core function is to act as a thread adapter, enabling seamless compatibility between equipment with different thread standards, ensuring optimal performance of your drill string.

# 1. Product Identification

The product name clearly defines its key specifications:

* Drill Rod: The product type.

* 12’: A total length of 12 Feet (approx. 3.66 meters).

* R38-R32: Features an R38 thread on one end and an R32 thread on the other.

# 2. Core Function & Value

Primary Function: Bridge and Adaptor

The core value of this rod lies in its adaptation capability. It seamlessly connects equipment using the larger R38 thread system with drill strings and tools using the more universal R32 thread system.

Problem It Solves:

If your rock drill (e.g., certain hydraulic rock drills) is equipped with an R38 shank, but your drill bits, DTH hammers, or other extension rods use the standard R32 thread, they cannot be connected directly. This 12’ R38-R32 Adapter Rod is the professional solution for this exact scenario.

# 3. Technical Specifications

| Item | Specification | Notes |

| Product Type | Adapter Drill Rod / Transition Rod | Different thread types on each end |

| Total Length | 12 Feet | Equivalent to 3.66 meters |

| Thread One | R38 (Female) | Typically connects to the rock drill or R38 shank adapter |

| Thread Two | R32 (Male) | Typically connects to R32 drill bits or extension rods |

| Thread Profile | Rope Thread | Specifically engineered to withstand high-impact stress and torque, ensuring reliable connection and long service life |

| Primary Material | High-Strength Alloy Steel | Provides excellent wear resistance and fatigue strength |

# 4. Typical Application Scenario

This adapter rod plays a critical role in the following drill string assembly:

Rock Drill (R38 Interface) → This Adapter Rod (R38 end) → This Adapter Rod (R32 end) → R32 Standard Drill Bit / Extension Rod / DTH Hammer

Ideal for Industries:

* Mining and Quarrying

* Construction and Civil Engineering

* Water Well Drilling

* Geological Exploration

# 5. Key Advantages

* Superior Compatibility: Perfectly solves the mismatch between R38 and R32 equipment.

* Increased Equipment Utilization: Allows your standard R32 drill tools to be used with R38-equipped drills, reducing the need for additional capital investment.

* High Reliability: Manufactured from premium steel with standard rope threads, ensuring durability and efficient transmission of impact energy.

* Operational Flexibility: An essential spare part for fleets operating a mix of drill rig brands and specifications.

Product Name: T45 Extension Rod, T45 Drill Steel, T45 Drill Rod

Product Overview

The T45 extension drill rod is a commonly used rock drilling tool, widely applied in open-pit bench drilling and underground production drilling.

This type of extension rod is a critical tool in top hammer drilling operations, particularly suitable for deep hole drilling conditions. When drilling at greater depths, the T45 extension rod effectively extends the drill string length, allowing the drill bit to reach deeper rock layers. When encountering hard rock layers or drilling obstacles, its extended length helps enhance the rock-breaking efficiency of the button bit and maintains a stable drilling process.

In confined or complex geological conditions, the T45 extension rod significantly improves operational adaptability, enabling more precise control over the drilling process.

The standard length of T45 extension rods ranges from 1.5 meters to 6 meters, with common specifications including 10 inches, 12 inches, and 14 inches. Shandike Rock Tools can provide customized lengths based on project requirements.

Whether for deep hole drilling, breaking through hard rock layers, or improving operational flexibility in tight spaces, the T45 extension rod is designed to enhance the efficiency and precision of rock drilling projects.

How to Choose the Right T45 Extension Drill Rod

The selection of drill rod material, cross-sectional shape, geometric dimensions, and length should comprehensively consider factors such as the impact power of the rock drill, rock hardness, drill bit diameter, drilling depth, connector specifications, and feeding method. Generally, while meeting the drilling requirements, priority should be given to drill rods with a moderate cross-section, good rigidity, and long service life. Shandike drill rods are manufactured using high-quality raw materials and special heat treatment processes, which significantly reduce the risk of thread part indentation. More precise manufacturing tolerance control ensures our products offer superior quality and durability.

T45 Drill Steel, T45 Extension Rod, Round 46

Drill rods, also known as drill pipes, are critical components used to connect the drill bit to the drilling rig. They facilitate the drilling process by transmitting rotational force and thrust to the drill bit, enabling it to penetrate the ground. Designed to withstand significant torque and pressure during operation, these rods are manufactured with high strength and exceptional wear resistance. Among them, the T38 drill rod is a category of top hammer drilling equipment widely employed in mining and tunnel construction. The term “T38” refers specifically to the thread type and dimensional standards of the drill rod.

Specifications of T38 Drill Rods

Extension Rods

Extension rods, also referred to as M/M drill rods, feature male threads on both ends. Below are common specifications for T38 extension rods:

1. Hex Rods

M/M, T38-H32-R32-2700mm, flushing hole: 16mm

M/M, T38-H32-R32-3090mm, flushing hole: 16mm

M/M, T38-H32-R32-3700mm, flushing hole: 16mm

M/M, T38-H32-R32-4300mm, flushing hole: 16mm

M/M, T38-H32-R32-4915mm, flushing hole: 16mm

M/M, T38-H32-R32-5525mm, flushing hole: 16mm

M/M, T38-H35-R32-2700mm, flushing hole: 16mm

M/M, T38-H35-R32-3090mm, flushing hole: 16mm

M/M, T38-H35-R32-3700mm, flushing hole: 16mm

M/M, T38-H35-R32-4300mm, flushing hole: 16mm

M/M, T38-H35-R32-4915mm, flushing hole: 16mm

M/M, T38-H35-R32-5525mm, flushing hole: 16mm

2. Round Rods

M/M, T38-RD39-T38-1220mm, flushing hole: 14.5mm

M/M, T38-RD39-T38-1525mm, flushing hole: 14.5mm

M/M, T38-RD39-T38-1830mm, flushing hole: 14.5mm

M/M, T38-RD39-T38-3660mm, flushing hole: 14.5mm

M/M, T38-RD39-T38-4270mm, flushing hole: 14.5mm

3.Speed Rods

Speed rods, or M/F rods, are designed with one male and one female thread end, allowing direct connection with other rods for deeper drilling without requiring a coupling sleeve. Common specifications include:

M/F, T38-RD39-T38-1220mm, flushing hole: Ø14.5mm, Female end OD: 56mm

M/F, T38-RD39-T38-1525mm, flushing hole: Ø14.5mm, Female end OD: 56mm

M/F, T38-RD39-T38-1830mm, flushing hole: Ø14.5mm, Female end OD: 56mm

M/F, T38-RD39-T38-3050mm, flushing hole: Ø14.5mm, Female end OD: 56mm

M/F, T38-RD39-T38-3660mm, flushing hole: Ø14.5mm, Female end OD: 56mm

M/F, T38-RD39-T38-4270mm, flushing hole: Ø14.5mm, Female end OD: 56mm

Guide Rods

T38-RD46-T38-1220mm, flushing hole: Ø17mm, Female end OD: 56mm

T38-RD46-T38-1830mm, flushing hole: Ø17mm, Female end OD: 56mm

T38-RD46-T38-3660mm, flushing hole: Ø17mm, Female end OD: 56mm

T38-RD46-T38-4265mm, flushing hole: Ø17mm, Female end OD: 56mm

Guide Tubes

T38-RD56-T38-1830mm, Diameter: 64mm

T38-RD56-T38-1830mm, Diameter: 64mm

T38-RD56-T38-3050mm, Diameter: 64mm

T38-RD56-T38-3660mm, Diameter: 64mm

T38-RD64-T38-3660mm, Diameter: 76mm

These standard specifications and parameters assist engineers and technicians in selecting suitable T38 drill rods to enhance drilling efficiency and project quality in various applications. The appropriate model should be chosen based on specific project needs and geological conditions. It is also essential to perform regular inspection and maintenance to ensure all connections remain secure, and to check for significant surface wear or cracks. Such practices help prolong the service life of the rods and maintain drilling operational safety.

T38 drill rod is a critical tool in rock drilling and mineral extraction. It is often used in conjunction with drill bits, shank adapters, and drilling rigs for the extraction of underground resources such as minerals, oil, natural gas, or groundwater, as well as for geological exploration.

Specification Selection

Specific applications require corresponding rig models, hence demanding matching drill rod specifications. For example:

Classification Overview

T38 drill rods are mainly divided into extension drill rods (also called MM rods) and speed drill rods (or MF rods). Both are designed based on the T38 thread standard, with key differences in their connection methods and functions:

T38 MM Drill Rod: This is a standard T38 threaded drill rod where “MM” stands for “Male-Male”, meaning both ends of the rod feature external threads. One end connects to the shank adapter, and the other end connects to the drill bit for rock drilling operations. To achieve greater drilling depth, a coupling sleeve must first be connected before adding another drill rod.

T38 MF Drill Rod: “MF” denotes “Male-Female”, meaning one end has an external thread while the other has an internal thread. This design allows another drill rod to be connected directly without a coupling sleeve, significantly saving operation time and labor costs.

Introduction to T38 Drill Rod

T38 drill rod specifically refers to a drill rod with T38 thread connections, a special type of steel rod designed for drilling operations, particularly in mining and construction. “T38” indicates the type and size of the threads used to connect drill bits or other drilling tools to the drill pipe, and it is one of the common thread specifications in the drilling industry. This type of drill rod is generally made of high-strength alloy steel to withstand various complex geological conditions and demanding working environments.

First, let us introduce the different characteristics of the two drilling tools.

Core Principle

Top Hammer (TH): The hammer/piston is mounted on the drilling rig above ground. It strikes the top of the drill string, sending shock waves down the rods to the bit.

Down-The-Hole (DTH): The hammer (including the piston) is located down the hole, immediately behind the bit. Compressed air drives the piston to strike the bit directly.

Differences & Characteristics

Comparison of two drilling technologies

| Feature | Top Hammer (TH) | Down-The-Hole (DTH) |

| Hammer Location | On the rig, above ground | In the hole, directly behind the bit |

| Energy Transfer | Impact travels down drill rods (energy loss with depth) | Impact directly on bit (minimal energy loss) |

| Optimal Depth | Shallow to Medium (Typically < 25m) | Medium to Deep (Effectively > 10m, often 100m+) |

| Hole Diameter | Small to Medium (Typically 35mm – 115mm) | Medium to Large (Typically 90mm – 300mm+) |

| Best Rock Type | Soft to Medium Hard | Medium Hard to Very Hard & Abrasive |

| Penetration Rate | Faster in soft/medium rock at shallow depths | Faster in hard rock & significantly faster at depth |

| Hole Straightness | Less accurate (deviation increases with depth) | More accurate & straighter holes |

| Water/Fluid | Dry drilling, or with air/flush mist | Handles wet conditions well (air flushes cuttings) |

| Noise/Vibration | High noise/vibration at the rig | Noise/vibration underground, quieter at surface |

| Dust Control | Requires good dust suppression (dry) | Air flush provides better dust control (into hole) |

| Bit Type | Cross-bit or Button-bit (shank adaptor) | Large, robust Button Bit (integral to hammer) |

| Setup/Complexity | Generally simpler rig setup | Requires larger air compressors, more complex hammer |

| Cost (Generally) | Lower capital cost (rig), higher rod wear cost | Higher capital cost (compressor/hammers), lower energy loss |

When to Use Which?

Choose Top Hammer (TH) When:

Drilling shallow holes (< 15-25m).

Working in soft to medium-hard rock.

Hole diameter is small (< 100mm).

Mobility and speed in shallow applications are critical (e.g., scaling, bolting).

Capital cost is a major constraint.

Precision hole straightness is less critical.

Choose Down-The-Hole (DTH) When:

Drilling deeper holes (> 10m, especially > 25m).

Working in hard, very hard, or abrasive rock.

Hole diameter is medium to large (> 90mm).

Hole straightness and accuracy are critical (e.g., production blasting, foundation piles).

Higher penetration rates in hard rock are needed.

Conditions are wet or require efficient cuttings removal.

Surface noise needs to be minimized.

Typical Applications

Top Hammer Tools:

Rock Bolting (Roof/ground support)

Scaling

Small-diameter Blast Holes (in softer rock/quarries)

Exploration Drilling (shallow)

Trenching

Anchoring (shallow)

Down-The-Hole:

Production Blast Holes (Mining, Quarrying – especially hard rock)

Large-Diameter Foundation Piling

Water Well Drilling

Deep Exploration Drilling

Geothermal Drilling

Piggyback Holes (Ventilation, backfill)

Conclusion

TH = Shallow & Fast (in soft rock): Best for smaller, shallower holes in softer formations where rig speed and lower upfront cost matter most. Energy loss limits depth effectiveness.

DTH = Deep & Hard: Essential for deeper holes, especially in hard rock, where direct energy transfer ensures higher efficiency, straighter holes, and superior penetration rates despite higher initial setup costs.

The choice fundamentally depends on rock hardness, required depth, hole diameter, precision needs, and budget. For deep holes in hard rock, DTH is almost always the superior choice. For shallow bolting or small holes in softer rock, TH is highly efficient.

In the depths of underground mine drifts, efficient and reliable drilling is paramount for productivity and safety. Facing extreme challenges—confined spaces, hard rock formations, relentless vibration, and abrasive dust—the performance of drill steel directly dictates penetration rates, hole accuracy, and equipment longevity. Engineered to conquer these demands, the Hex32 Drifter Rod stands as a pinnacle of drilling technology, combining advanced materials science and precision design to deliver unparalleled performance in underground xcavation.

Confronting the Challenge: The Harsh Realities of Underground Drilling

Space Constraints: Narrow drifts demand drill steel with exceptional stiffness and bending resistance to maintain borehole precision.

Hard Rock Formations: Efficient fragmentation of tough ores requires rods capable of transmitting high impact energy and rotational torque.

Continuous High Load: Repeated impact stress creates severe fatigue failure risks.

Abrasive Conditions: Dust, moisture, and collisions demand superior wear resistance and overall toughness.

Efficiency & Cost: Frequent rod replacement cripples operational efficiency and drives up costs.

Hex32 Drifter Rod: Engineering Excellence Embodied

The Hex32 is not ordinary drill steel. Designed as a core consumable for heavy-duty underground drill rigs (e.g., Sandvik Simba, Epiroc Boomer), its name reveals its defining features: a Hexagonal (Hex) cross-section forged from high-strength alloy steel, with a standard shank diameter of 32 mm. This unique design delivers unmatched advantages:

Core Value: Driving Underground Mine Productivity

Increased Penetration Rates: Higher energy transfer efficiency and superior rock fragmentation translate directly to faster meter-per-minute drilling, shortening cycle times.

Guaranteed Hole Accuracy: Exceptional stiffness minimizes deviation, enabling precise blasting and drift profiling, reducing overbreak and underbreak.

Extended Service Life: Outstanding fatigue and wear resistance drastically reduce unplanned rod changes, lowering consumable costs and maintenance downtime.

Reduced Total Operating Cost (TOC): Longer rod life, less downtime, and higher productivity combine to lower cost per ton mined.

Enhanced Operational Safety: Minimizes risks associated with rod breakage or failure, providing high reliability through robust design.

Ideal Applications:

The Hex32 Drifter Rod excels in:

Development and production drilling in underground metal mines (gold, copper, iron ore).

Long-hole and medium-length hole stoping.

Other underground excavations requiring high-precision, high-efficiency drilling (e.g., hydropower tunnels, roadway bolting).

Choose Hex32: Choose Reliable Productivity

In the high-stakes, cost-sensitive environment of underground mining, the Hex32 Drifter Rod, with its hexagon-driven rigidity, efficient power transmission, extended durability, and seamless compatibility, is the preferred solution for mines demanding efficiency, precision, and lower operating costs. It is more than a link between the drill and the bit; it is the robust backbone driving sustained underground advancement. Investing in high-quality Hex32 rods is an investment in a mine’s stable, productive, and safe future.

| Feature | Specification / Description |

|---|---|

| Shank Profile | Hexagonal |

| Shank Diameter | 32 mm |

| Material Grade | High-Strength Alloy Steel (e.g., 35SiMnMoV) |

| Heat Treatment | Quenching & Tempering (Hardening + High-Temp Tempering) |

| Impact Toughness | ≥ 12 J (Charpy V-notch, Room Temp) |

| Thread Types | R32, T38, T45 (Other standard underground threads available) |

| Critical Zone Treatment | Thread Induction Hardening / Shot Peening |

| Surface Treatment | Copper Plating, Zinc Phosphating, or other anti-corrosive/anti-wear coatings |

| Key Advantages | High Stiffness, Efficient Power Transfer, Fatigue Resistance, Long Life, Excellent Compatibility |

Pneumatic rock drills are fundamental tools in mining, quarrying, and construction for drilling blast holes. While the drill itself delivers the percussive force, optimal performance relies heavily on two critical consumables: the drill rod and the drill bit. Understanding their roles and interaction is key to efficient and productive drilling.

Rods and bits work inseparably:

Choosing the right rod and bit combination depends on:

Rock Type & Hardness: Dictates bit type (button profile) and carbide grade.

Hole Diameter: Determines bit size and required rod diameter/shank size.

Hole Depth: Dictates the number and length of extension rods needed.

Drill Model & Power: Must match the shank/thread size (e.g., R32, T38) and be compatible with the drill’s power output.

Flushing Medium: Air or water? Impacts bit design (e.g., water ports).

Conclusion

Drill rods and bits are far more than simple accessories for pneumatic rock drills; they are precision-engineered, consumable components fundamental to the drilling process. Their quality, compatibility, and condition directly dictate drilling speed, efficiency, hole quality, and operational costs. Selecting the appropriate rod and bit combination for the specific rock conditions and drill, and maintaining them properly, is essential for achieving safe, productive, and cost-effective drilling operations. Focus on thread integrity, material quality, and timely replacement to maximize performance.

High-Strength Carbon Steel Tapered Drill Rods

Core Benefits: Exceptional Toughness, Efficient Energy Transfer, Engineered for Heavy-Duty Percussive Drilling.

Overview:

Carbon Steel Tapered Drill Rods are essential consumables for heavy-duty percussive drilling in demanding applications such as mining, quarrying, tunnel boring, and construction. Manufactured from premium high-carbon steel and subjected to precision heat treatment, these rods deliver outstanding hardness, impact resistance, and fatigue strength. The unique tapered design ensures rapid, reliable connection to drill bits or extension rods, enabling efficient power transmission for deep-hole drilling operations.

Key Features & Advantages:

Heat treatment of tapered drill rods is crucial to ensure they possess the necessary hardness, toughness, and wear resistance for drilling applications. The tapered geometry introduces challenges such as uneven cooling rates and potential distortion. Below are two primary heat treatment methods tailored for tapered drill rods, along with key considerations:

Process Steps:

1. Austenitizing: Heat the entire rod uniformly to the austenitizing temperature (e.g., 830–870°C for 4140 steel).

2. Quenching: Rapidly cool in oil (preferred over water to minimize thermal stress) to form martensite.

3. Tempering: Reheat to 400–600°C to reduce brittleness and achieve a balance of hardness and toughness.

Benefits:

Provides uniform core hardness and strength.

Suitable for highcarbon or alloy steels (e.g., 4140, 4340).

Challenges for Tapered Rods:

Uneven cooling: Thicker sections cool slower, risking soft spots or distortion.

Mitigation: Use agitated oil quenching or polymer quenchants for controlled cooling.

PostTreatment:

Straightening may be required if warping occurs.

Hardness testing along the taper (e.g., Rockwell C scale) to ensure consistency.

Process Steps:

1. Localized Heating: Use an induction coil to heat the tapered surface to austenitizing temperature.

2. Quenching: Immediate spray quenching (water or polymer) to harden the surface.

3. Tempering: Lowtemperature tempering (150–200°C) to relieve stresses.

Benefits:

Hardens only the surface, preserving a tough core.

Minimizes distortion compared to full hardening.

Ideal for applications requiring wearresistant surfaces (e.g., drill rod threads).

Challenges for Tapered Rods:

Coil design: Requires precise coil alignment to maintain consistent heating along the taper.

Variable case depth: Thinner sections may overheat; automated coil movement or variable power settings can address this.

PostTreatment:

Eddy current testing to verify case depth uniformity.

Additional Considerations

PreTreatment:

Stressrelief annealing after machining to reduce residual stresses.

Normalizing to refine grain structure for consistent hardening.

Alternative Methods:

Nitriding: Lowtemperature surface hardening (500°C) for minimal distortion.

Austempering: Interrupted quenching in a salt bath to reduce warping.

MaterialSpecific:

Highcarbon steels prioritize hardness; alloy steels (e.g., 4140) balance toughness and wear resistance.

By selecting the appropriate method and controlling process parameters (e.g., quench medium, coil speed), tapered drill rods can achieve optimal performance with minimal distortion. Posttreatment inspection is critical to ensure geometric integrity and mechanical properties.

Threaded drill rods are critical components in drilling operations, widely used in mining, oil and gas exploration, and geotechnical engineering. Failures in these components can lead to costly downtime, safety hazards, and operational inefficiencies. A systematic failure analysis is essential to identify root causes and implement corrective measures. Below is a structured approach to analyzing failures in threaded drill rods:

Fatigue Fracture:

Cyclic loading during drilling induces stress concentrations at thread roots or transitions, leading to crack initiation and propagation.

Often characterized by beach marks or ratchet marks on fracture surfaces.

Overload Failure:

Sudden fracture due to excessive axial/torsional loads (e.g., hitting hard formations or obstructions).

Features include brittle fracture surfaces or plastic deformation.

Wear and Galling:

Thread wear, abrasion, or material transfer due to poor lubrication, misalignment, or inadequate hardness.

Corrosion-Induced Failure:

Pitting, stress corrosion cracking (SCC), or hydrogen embrittlement in corrosive environments (e.g., acidic or saline conditions).

Manufacturing Defects:

Inclusions, porosity, improper heat treatment, or machining errors (e.g., incorrect thread geometry).

Material Selection:

Inadequate steel grade (e.g., low toughness or hardness) for the application.

Poor resistance to corrosion or hydrogen embrittlement.

Design Flaws:

Insufficient thread root radius, sharp transitions, or inadequate stress distribution.

Operational Conditions:

Excessive torque, vibration, or bending stresses.

Drilling in abrasive or corrosive formations.

Maintenance Issues:

Lack of lubrication, improper handling, or failure to replace worn components.

Visual Inspection:

Document fracture surface morphology, wear patterns, and corrosion.

Metallurgical Analysis:

Microstructure examination (e.g., grain size, decarburization) using optical microscopy or SEM.

Hardness testing to verify heat treatment consistency.

Fractography:

SEM/EDS analysis to identify fracture mechanisms (e.g., fatigue striations, cleavage facets).

Chemical Analysis:

Verify material composition (e.g., carbon content, alloying elements).

Non-Destructive Testing (NDT):

Ultrasonic testing, magnetic particle inspection, or dye penetrant to detect subsurface cracks.

Stress Analysis:

Finite element analysis (FEA) to evaluate stress distribution in threads.

Scenario: Fatigue failure of a drill rod thread in a mining operation.

Findings:

Beach marks on the fracture surface indicated cyclic fatigue.

Microscopic analysis revealed microcracks initiating at thread roots due to stress concentration.

Hardness testing showed inconsistent heat treatment (soft spots).

Root Cause: Poor thread design (sharp root radius) combined with suboptimal heat treatment.

Solution:

Redesign threads with larger root radii.

Implement stricter quality control for heat treatment processes.

Design Optimization:

Increase thread root radii, use tapered threads, or apply shot peening to enhance fatigue resistance.

Material Upgrades:

Use high-grade alloy steels (e.g., 4140/4340) with corrosion-resistant coatings (e.g., phosphate, DLC).

Improved Manufacturing:

Ensure precise machining, proper heat treatment (quenching and tempering), and stress-relief annealing.

Operational Best Practices:

Monitor torque/load limits, use appropriate drilling fluids for lubrication, and avoid over-tightening connections.

Regular Maintenance:

Inspect threads for wear/cracks, replace damaged rods, and enforce proper storage to prevent corrosion.

Failure analysis of threaded drill rods requires a multidisciplinary approach combining metallurgy, mechanical engineering, and operational insights. Addressing root causes through design improvements, material upgrades, and proactive maintenance can significantly extend service life and enhance drilling efficiency. Continuous monitoring and adherence to industry standards (e.g., API, ISO) are critical to mitigating risks in demanding drilling environments.

January 11, 2024

January 11, 2024